PRODUCT

PRODUCT

Welding smoke purification system

Welding smoke purification system

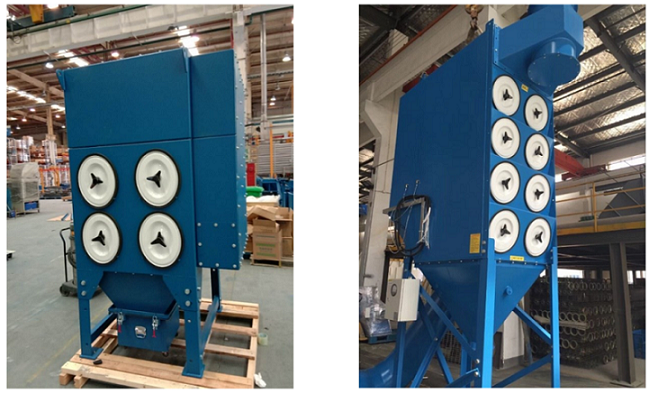

Maxi series soot filter system

Maxi is a high-efficiency filtering device suitable for soot and dust, which can easily filter the soot dust generated in the metal processing industry. The processing capacity of this series of filters can reach up to 80,000m³/h air volume; they can meet the customers by configuring filters of different materials. The need for special working conditions such as high filtration efficiency and anti-static.

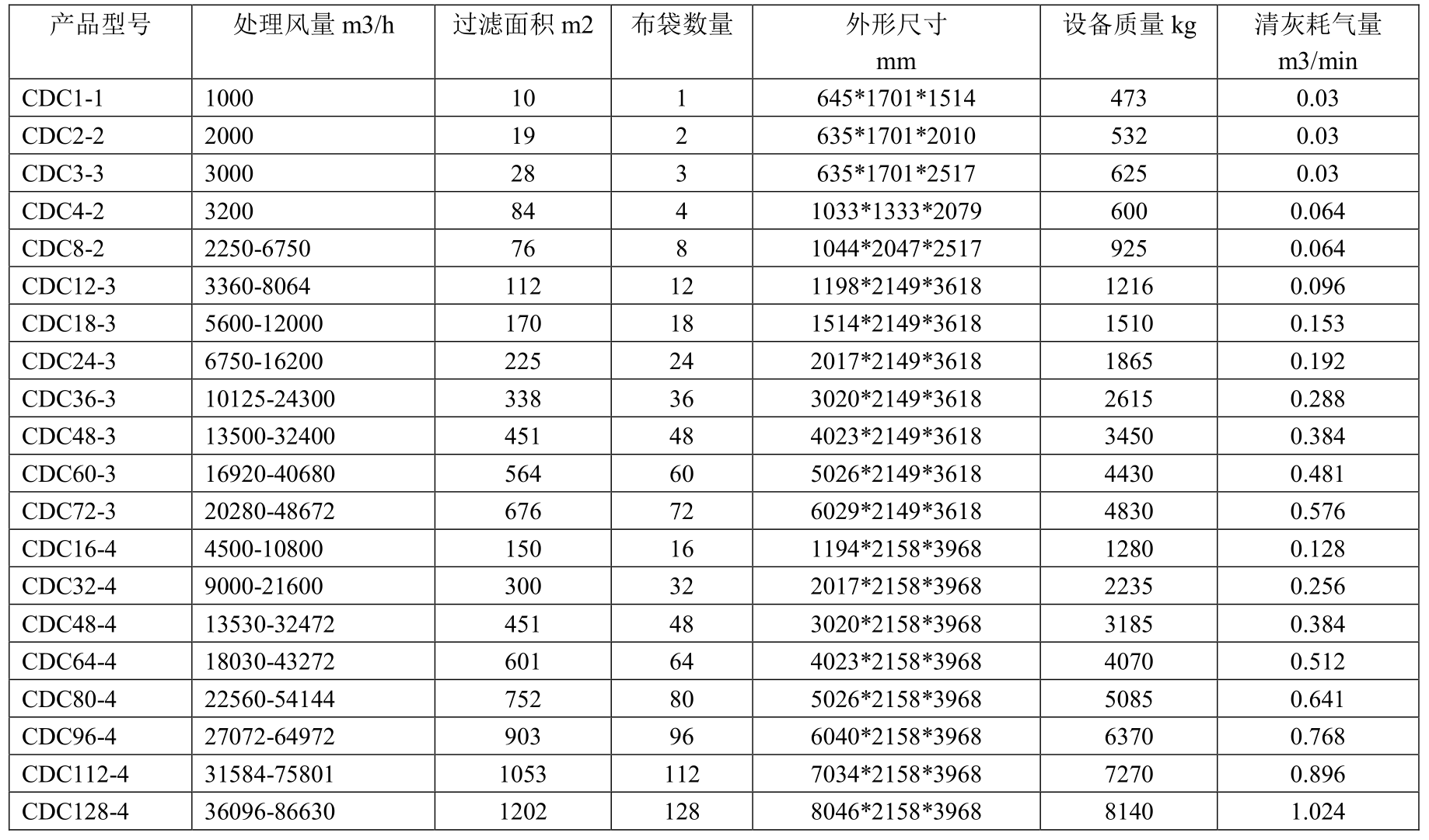

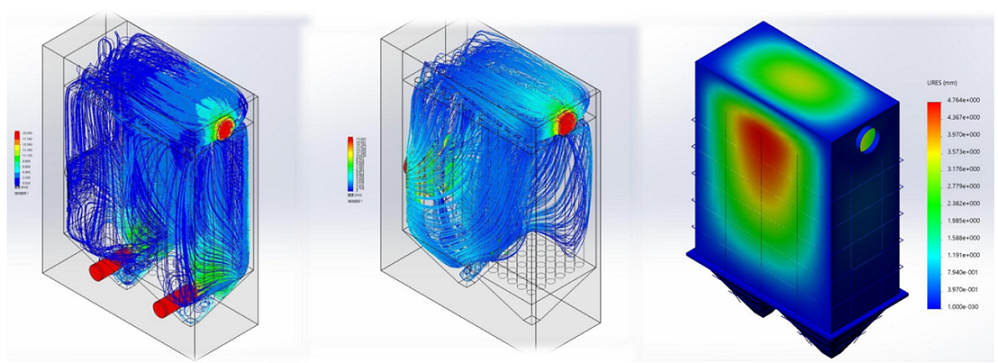

The Maxi filter is equipped with an automatic pulse cleaning system to achieve online cleaning of the filter. If necessary, offline cleaning can be achieved. Both

air permeability and high filter accuracy filter core materials are considered.

According to the needs of explosion-proof, it can be configured as an explosion-proof smoke and dust filter

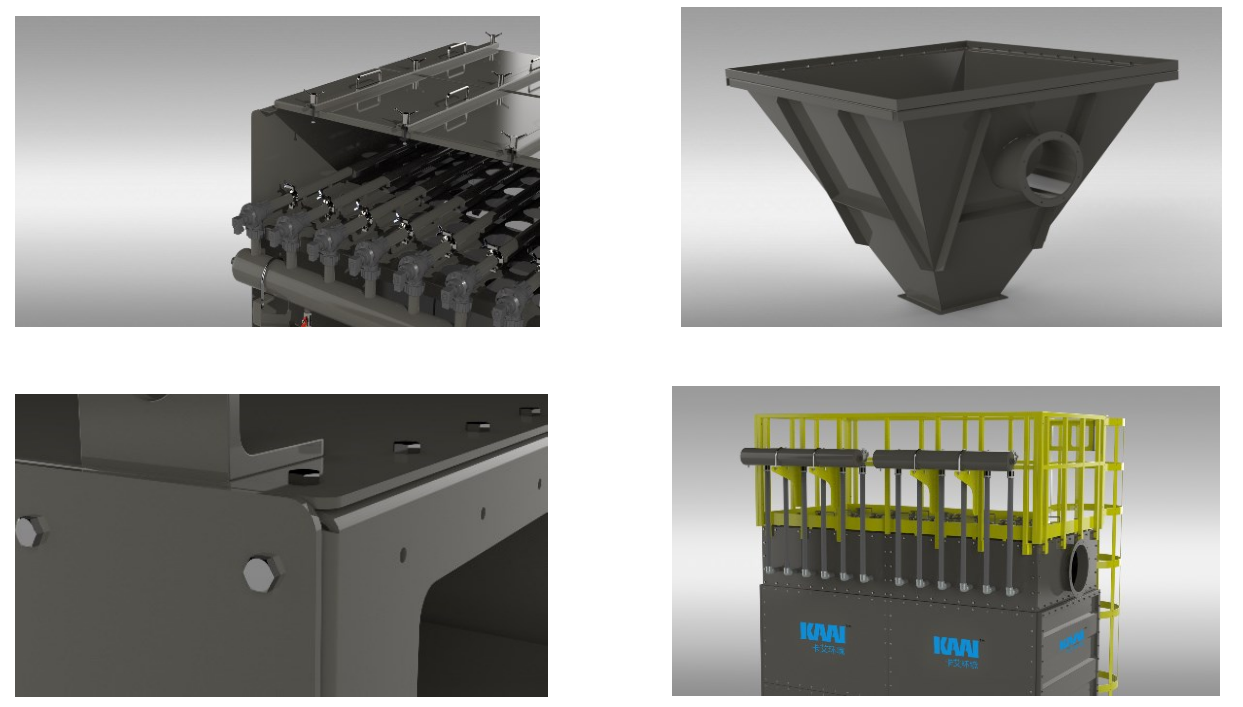

module Design, processing, and assembly to easily meet customer needs for various processing air volumes

Soot Purifier Selection Table

Maxi filter advantages

Abundant product models to meet customers' various air volume requirements

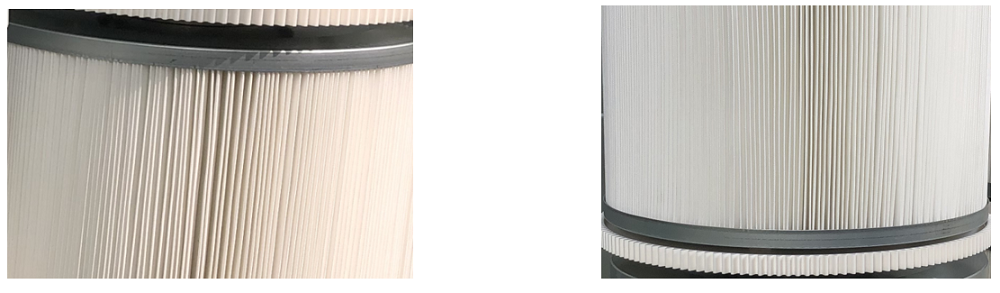

According to different dust characteristics, choose filter elements with different filter materials

Modular design, free assembly, superb processing technology

Mass production, quality controllable

Equipped with a turbo fan with excellent performance, it can realize the perfect combination of large air volume and high negative pressure

Optional nano-fiber filter material can effectively filter 0.3-1 micron micro particles to achieve higher filtration efficiency

Through PTFE coating, meet the needs of special working conditions such as antistatic, flame retardant, oil-proof and waterproof, ultra-fine dust, etc.

Superb technology, computer design, simulation test

Optimized airflow design

Efficient imported filter material

Welding generates smoke and dust and releases harmful gases and particles. Welding-related operations, such as grinding, cutting, and polishing, also produce the above-mentioned harmful substances. The smoke particles are mainly formed by the evaporation of metals and flux. As the steam cools, the steam condenses and reacts with oxygen in the atmosphere to form fine particles.

At the welding source, the diameter of welding fume particles can be from 0.01 to greater than 0.1 μm . When the particles reach the welder's breathing area, polymerization has occurred and become particles of 1-2 μm in size. Particles greater than 5 μm are attached to the upper respiratory tract. Particles in the range of 0.1-5μm, including welding fumes and dust, can penetrate the internal cells of the lungs and settle down, causing harm to the human body

In addition, many processes produce various gases (carbon dioxide and ozone are the most common, but there are other gases at the same time), and these gases can also be dangerous if there is insufficient ventilation.

Application industry

Welding dust removal of metal workpieces Plasma cutting soot purification

Metal workpiece polishing soot purification Robot automatic welding soot purification

Cases

Partner

Contact us