PRODUCT

PRODUCT

Oil mist purification system (centralized)

Oil mist purification system (centralized)

Overview :

The electrostatic oil mist purifier has the characteristics of low resistance and no replacement of filter materials, and the operation and maintenance costs are extremely low. The diameter of filterable particles can be as small as 0.01 microns, and the purification efficiency is high. After air purification, it can be directly discharged to the production workshop. We can provide a variety of products with 500-50000m3/h air volume

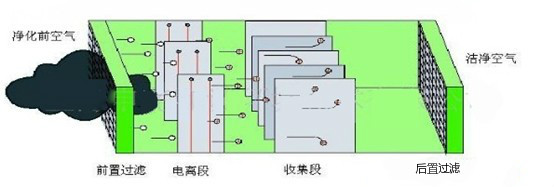

Purification principle:

Pre-filtration: It is composed of high-polished vortex filter and stainless steel wire filter. It can filter most of the large particle oil mist. Different configurations can be selected according to the type and concentration of oil mist on site.

Ionization section: An electric field is formed between the high-voltage electrode wire and the electrode plate to ionize the small particle oil mist to make it charged.

Collection section: The charged particles are adsorbed on the electrode plate, converge into oil droplets and flow into the recovery tank along the smooth surface of the electrode plate.

Post-filtering: To enhance purification efficiency, high-efficiency filters or activated carbon filters can be configured according to the needs of the site.

Product features :

1. Stable high-voltage power module.

a) High stability, which has been tested for more than 20 years.

b) High-voltage alarm function, when poor maintenance causes short circuit between the poles, the module automatically protects and outputs an alarm.

c) Voltage adjustment function, the output voltage can be adjusted within ±10%.

d) Alarm delay setting.

2. The vortex oil mist separation technology designed using aerodynamic principles is very efficient for purification of high-concentration oil mist, and it is maintenance-free during use.

3. Use Eff1 high-efficiency motors that meet the European Union IEC 60034-30:2008 and IEC 60034-2-1:2007 standards, saving 15% of power consumption.

4. The equipment is equipped with a separate safety switch, which basically guarantees the safety of the operator and prevents the occurrence of high-voltage electric shock accidents caused by misuse.

5. The original seal design ensures zero leakage of oil mist.

6. All filter element full drawer design, maintenance is extremely convenient.

7. Modular combination design

8, 20 years of technology and experience accumulated more professional

Parameter table of centralized oil mist purification system:

|

model |

Number of modules

|

Maximum air volume (m3/h) |

Collection area (㎡) |

Length (mm) |

Width (mm) |

Height (mm) |

|

Module 3500

Module 7000

Module 10500

Module 7000

Module 14000

Module 21000

Module 10500

Module 21000

Module 31500

Module 14000

Module 28000

Module 42000 |

1 |

3500 |

26 |

750 |

620 |

710 |

|

2 side by said |

7000 |

52 |

750 |

1240 |

710 |

|

|

3 side by said |

10500 |

78 |

750 |

1860 |

710 |

|

|

|

|

|

|

|

|

|

|

2 (2×1) |

7000 |

52 |

750 |

620 |

1420 |

|

|

4 (2×2) |

14000 |

104 |

750 |

1240 |

1420 |

|

|

6 (2×2) |

21000 |

156 |

750 |

1860 |

1420 |

|

|

|

|

|

|

|

|

|

|

3 (3×1) |

10500 |

78 |

750 |

620 |

2130 |

|

|

6 (2×3) |

21000 |

156 |

750 |

1240 |

2130 |

|

|

9 (3×3) |

31500 |

234 |

750 |

1860 |

2130 |

|

|

|

|

|

|

|

|

|

|

4 (4×1) |

14000 |

104 |

750 |

620 |

2840 |

|

|

8 (4×2) |

28000 |

208 |

750 |

1240 |

2840 |

|

|

12 (4×3) |

42000 |

312 |

750 |

1860 |

2840 |

Examples show:

Scope of application: oil mist/water mist/flue gas produced by cutting oil, water-based emulsions and synthetic coolants during processing, and the purification of oil smoke exhaust gas from other industrial waste gas.

Application places: lathe milling machine, drilling machine grinder, cold heading in mechanical processing Machine, heat treatment, die casting machine, vacuum pump and other production and processing places of oil fume and oil mist purification

application industry: bearing manufacturing oil fume and oil mist purification, tool manufacturing oil fume and oil mist purification, automobile parts manufacturing oil fume and oil mist purification, IT equipment manufacturing Oil mist purification, oil smoke mist purification in petrochemical industry, etc.

Our service capabilities

1) 10 years of experience in oil mist control

2) Technical team with professional qualities in project design and project construction management

3) Professional, timely and efficient after-sales service team

4) From surveying customer site => scheme design => equipment selection => construction and installation => to after-sales maintenance service, complete service system

5) Provide value-added services for customers to monitor and compare exhaust gas concentration before and after construction of the project, and verify the results with data

6) A large number of customer cases across the country, and higher customer satisfaction

Installation method

1) Stand-alone stand installation

2) Machine-mounted installation

3) Indoor ceiling installation

4) Outdoor roof installation

5) Local concentration

6) Centralized indoor collection and outdoor installation of equipment

Cases

Partner

Contact us