PRODUCT

PRODUCT

Mechanical oil mist purifier

Mechanical oil mist purifier

Overview:

The mechanical oil mist purifier has the characteristics of wide application range, high filtration efficiency, and easy replacement of filter materials. After air purification, it can be directly discharged to the production workshop. Modular design, can provide 800-50000m3/h various specifications products

Product features :

1) Based on modular design, the air volume can be arbitrarily combined according to needs

2) Self-cleaning filter: There is an oil drain hole under the filter. Because the filter is placed vertically, the filtered oil can automatically flow to the sewage tank according to gravity, and the maintenance interval is extended.

3) Purification efficiency: 99.9%. (German DIN 24185 standard)

4) IE2 high-efficiency motor can be selected

5) The filter section and the fan section are in the same chassis, the noise is smaller, and the equipment placement area is reduced

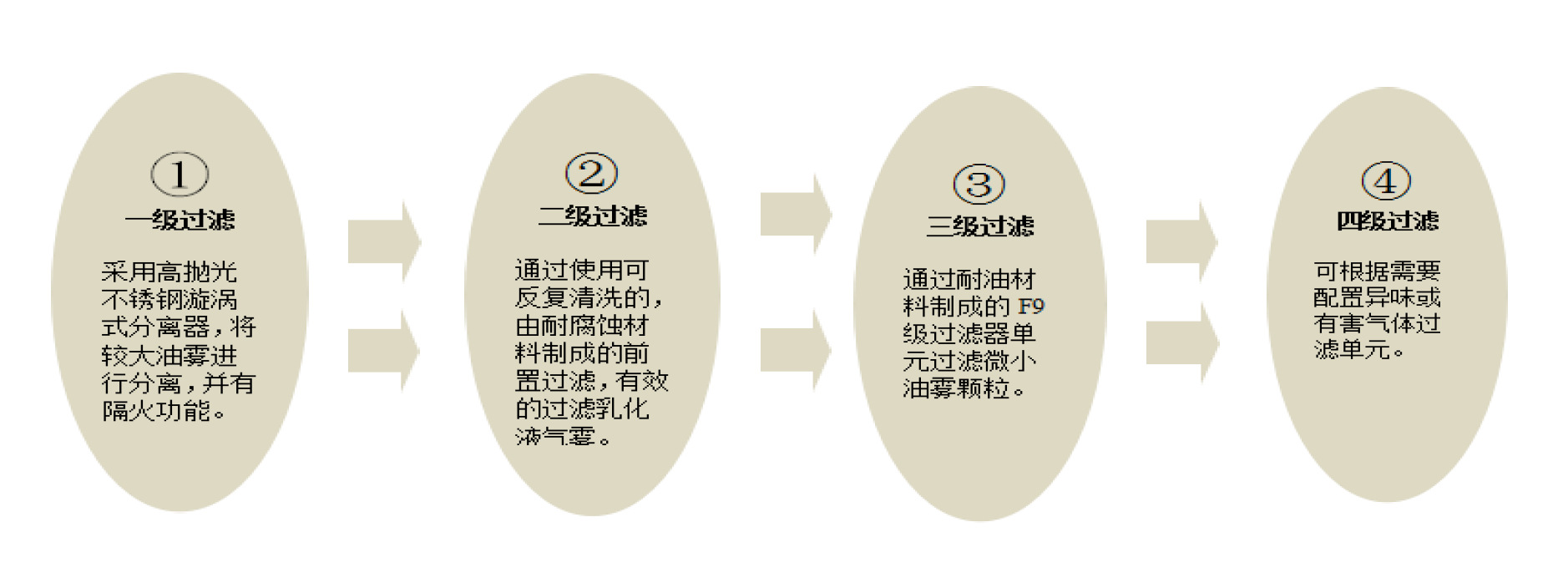

Filtration structure-(using four-stage filtration)

1) The first-level filtration uses a high-polished stainless steel vortex separator to separate large-particle oil mist.

2) Secondary filtration filters large oil mist particles through the stainless steel wire filter section.

3) The three-stage filter filters small oil mist particles through a filter section made of stainless steel and fabric materials.

4) Four-stage filtration filters fine oil mist particles through F9 grade filters made of oil-resistant materials.

5) High-efficiency filtration or activated carbon filtration can be configured according to the customer's site needs.

6) You can choose to mix with electrostatic filtration according to the needs of the scene.

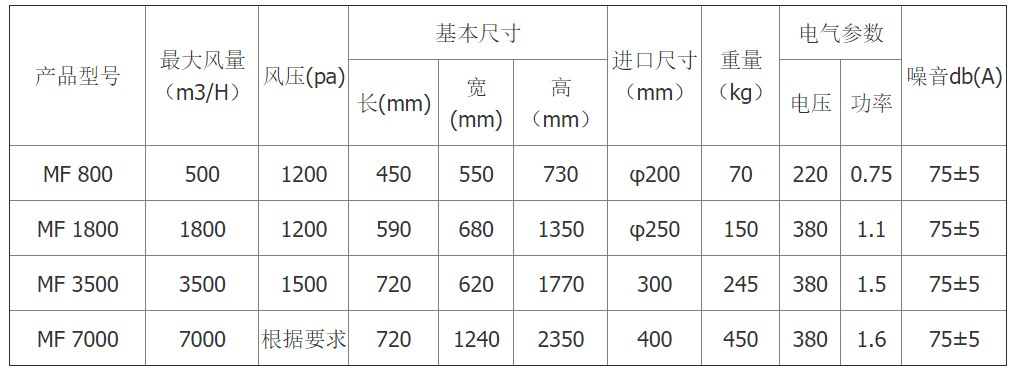

Product parameters:

Application range:

1) There are many cases of general water-based cutting fluid (emulsion)

2) Oil mist contains flammable and explosive oil mist, such as diesel, kerosene, gasoline, etc.

3) When the oil mist temperature is higher than 50°, special filter materials can be used at extremely high temperatures

4) The material of the processed workpiece is active metals such as titanium and zirconium

Application: Widely used in oil mist purification of lathe milling machine drilling machine grinder in various mechanical processing, cold heading machine, heat treatment, die casting machine, oiling machine and other production and processing occasions

Application industry: oil mist collection and purification in bearing manufacturing industry, oil mist collection and purification in tool manufacturing industry, oil mist collection and purification in automobile parts manufacturing industry, oil mist collection and purification in IT equipment manufacturing, oil mist collection and purification in petrochemical industry, etc.

Installation method:

1) Stand-alone stand installation

2) Machine-mounted installation

3) Indoor ceiling installation

4) Outdoor roof installation

5) Local concentration

6) Centralized indoor collection and outdoor installation of equipment

Example show:

Our service capabilities

1) 10 years of experience in oil mist control

2) The most professionally qualified project design engineer team

3) Professional, timely and efficient after-sales service team

4) From surveying customer site => scheme design => equipment selection => construction and installation => to after-sales maintenance service, complete service system

5) Provide value-added services for customers to monitor and compare exhaust gas concentration before and after construction of the project, and verify the results with data

6) A large number of customer case witnesses across the country and in various industries

Cases

Partner

Contact us